|

|

|

|

cracklover

cracklover

Jun 21, 2009, 4:51 AM

Post #1 of 47

(19061 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

For those of you interested in Aric's recent breaking of a bunch of Aliens, I did some work to collect some data on the effective angle of each cam he tested.

Edited to add: The angle I'm measuring is the angle between the center of the axle and the point of contact between the edge of the fixture at the moment before Aric began pulling.

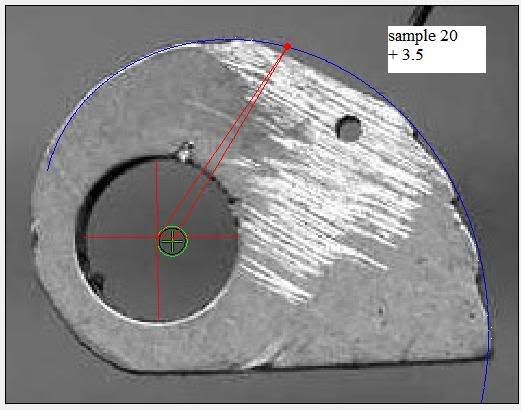

Hopefully this pic will clarify. Depicted is the right side cam lobe, the axle, and the right side of the fixture. The angle I'm measuring is the angle between the axle and the fixture at the moment before the cam starts getting pulled.

Methodology:

I used the photos Aric scanned in of the cam lobes post-pulling, found here: http://www.shariconglobal.com/...cans/lobe_scans.html

Second, I ran these photos through the Dorrington software to obtain a theoretical center point. (found here: http://www.dorringtonclimbing.com

Third, I found the contact point for each lobe, using a combination of the photos Aric took of the cam placed in the jig, and the flat spot on the cam lobe. Wherever possible, I used the actual flat spot.

Fourth, I determined the effective cam angle in the jig for each lobe, and averaged them together. For each cam Aric put photos online, I used between two and four lobes. If the lobes were too bent, or if the results were identical across lobes, I did not use all four.

Lastly, I averaged these angles together to find the effective cam angle for each piece Aric tested.

The reasons these photos are more accurate to run through the Dorrington software are four-fold. First, because they are layed flat on a scanner, they are properly oriented to the "camera". Second, because the axle and nut are removed, leaving the axle hole in the same plane, the center of the stem cannot "appear" to be offset due to a slight change in camera angle. The center of the axle is exactly where it is. Third, the flat spot in the cam lobe shows exactly where the lobe contacted the fixture. This is much superior to the guesswork of looking at a photo of the cam in the fixture and trying to estimate where lobes that are hidden by the closer lobes are contacting the fixture. And lastly, in some cases, the different lobes were cammed quite different amounts. Looking at the cams after the fact made this obvious, and gave much more accurate readings on where the contact point is. I was then able to average the angles together.

With all that said, here is the raw data:

sample size failure angle RATING

Number mode %

7 black pulled 19.3 64%

24 black pulled 21.0 54%

22 blue pulled 13.0 83%

23 blue pulled 18.2 69%

6 clear pulled 18.8 90%

17 grey pulled 21.5 98%

19 grey pulled 21.8 105%

2 orange pulled 14.8 74%

4 purple pulled 21.7 81%

5 purple pulled 22.7 89%

14 red broke cable 19.7 101%

12 red broke cable 19.8 100%

15 red/silver pulled 19.3 113%

16 red/silver broke cable 19.5 117%

21 yellow pulled 17.2 105%

9 yellow pulled 18.3 94%

3 yellow braze 18.5 78%

20 yellow pulled 18.7 83%

8 yellow pulled 18.8 93%

Looks like within a cam size, there may be some correlation between angle and pullout force, such that the higher the angle, the lower the force. But I'm tired, and I haven't run the numbers.

Here are the pics:

http://s26.photobucket.com/...gles/?albumview=grid

GO

(This post was edited by cracklover on Jun 22, 2009, 6:47 PM)

|

|

|

|

|

villageidiot

Jun 21, 2009, 5:22 AM

Post #2 of 47

(19044 views)

Shortcut

Registered: May 12, 2005

Posts: 104

|

Are you guy's just not that into controls or trying to do meaningful work?

|

|

|

|

|

jt512

Jun 21, 2009, 5:26 AM

Post #3 of 47

(19041 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

villageidiot wrote: Are you guy's just not that into controls or trying to do meaningful work?

Right question; wrong forum.

Jay

|

|

|

|

|

jt512

Jun 21, 2009, 5:30 AM

Post #4 of 47

(19037 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

cracklover wrote: For those of you interested in Aric's recent breaking of a bunch of Aliens, I did some work to collect some data on the effective angle of each cam he tested. Methodology: I used the photos Aric scanned in of the cam lobes post-pulling, found here: http://www.shariconglobal.com/...cans/lobe_scans.html Second, I ran these photos through the Dorrington software to obtain a theoretical center point. (found here: http://www.dorringtonclimbing.com Third, I found the contact point for each lobe, using a combination of the photos Aric took of the cam placed in the jig, and the flat spot on the cam lobe. Wherever possible, I used the actual flat spot. Fourth, I determined the effective cam angle in the jig for each lobe, and averaged them together. For each cam Aric put photos online, I used between two and four lobes. If the lobes were too bent, or if the results were identical across lobes, I did not use all four. Lastly, I averaged these angles together to find the effective cam angle for each piece Aric tested. The reasons these photos are more accurate to run through the Dorrington software are four-fold. First, because they are layed flat on a scanner, they are properly oriented to the "camera". Second, because the axle and nut are removed, leaving the axle hole in the same plane, the center of the stem cannot "appear" to be offset due to a slight change in camera angle. The center of the axle is exactly where it is. Third, the flat spot in the cam lobe shows exactly where the lobe contacted the fixture. This is much superior to the guesswork of looking at a photo of the cam in the fixture and trying to estimate where lobes that are hidden by the closer lobes are contacting the fixture. And lastly, in some cases, the different lobes were cammed quite different amounts. Looking at the cams after the fact made this obvious, and gave much more accurate readings on where the contact point is. I was then able to average the angles together. With all that said, here is the raw data: sample size failure angle RATING

Number mode %

7 black pulled 19.3 64%

24 black pulled 21.0 54%

22 blue pulled 13.0 83%

23 blue pulled 18.2 69%

6 clear pulled 18.8 90%

17 grey pulled 21.5 98%

19 grey pulled 21.8 105%

2 orange pulled 14.8 74%

4 purple pulled 21.7 81%

5 purple pulled 22.7 89%

14 red broke cable 19.7 101%

12 red broke cable 19.8 100%

15 red/silver pulled 19.3 113%

16 red/silver broke cable 19.5 117%

21 yellow pulled 17.2 105%

9 yellow pulled 18.3 94%

3 yellow braze 18.5 78%

20 yellow pulled 18.7 83%

8 yellow pulled 18.8 93% Looks like within a cam size, there may be some correlation between angle and pullout force, such that the higher the angle, the lower the force. But I'm tired, and I haven't run the numbers. Here are the pics: http://s26.photobucket.com/...gles/?albumview=grid GO

Gabe, have you been able to measure cam size? It will be difficult to control for the effect of cam size without such measurements. And without controlling for cam size, the analysis will be doomed.

Jay

|

|

|

|

|

villageidiot

Jun 21, 2009, 6:08 AM

Post #5 of 47

(19007 views)

Shortcut

Registered: May 12, 2005

Posts: 104

|

What's the merit in reporting the average of the cam angles? I am not much of a math person, but I believe you need 5 degrees of freedom to predict the actual cam angle of a log spiral with the axle off center (2 DOF to describe the cam, 2 DOF to describe where the axle is in relationship to the center of the spiral, and 1 DOF to describe how open the cam is).

|

|

|

|

|

cracklover

cracklover

Jun 21, 2009, 11:53 PM

Post #6 of 47

(18922 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

jt512 wrote: Gabe, have you been able to measure cam size? It will be difficult to control for the effect of cam size without such measurements. And without controlling for cam size, the analysis will be doomed. Jay

Nope, I have not measured cam size. Frankly, I neither see the point nor do I know what measurement you're looking for, or how you think I could get it.

If you want to know the volume of material that needs to be moved before reaching the 35 degree slipping point, you would need to know more than just some dimension whatever that single dimension is you're looking for.

GO

|

|

|

|

|

cracklover

cracklover

Jun 22, 2009, 12:04 AM

Post #7 of 47

(18911 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

villageidiot wrote: What's the merit in reporting the average of the cam angles?

Well, some of the cams appear to be pulling from the fixture when they flatten enough to create a 35 degree angle at the leading edge of the flat point.

So the theory is that if the cam starts with a higher angle, less force is required, because less metal has to be deformed.

In reply to: I am not much of a math person, but I believe you need 5 degrees of freedom to predict the actual cam angle of a log spiral with the axle off center (2 DOF to describe the cam, 2 DOF to describe where the axle is in relationship to the center of the spiral, and 1 DOF to describe how open the cam is).

Sorry, could you try that again in plain English? Or else just tell me what you see wrong with the methodology I actually used.

Thanks,

GO

|

|

|

|

|

jt512

Jun 22, 2009, 12:45 AM

Post #9 of 47

(18878 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

cracklover wrote: jt512 wrote: Gabe, have you been able to measure cam size? It will be difficult to control for the effect of cam size without such measurements. And without controlling for cam size, the analysis will be doomed. Jay Nope, I have not measured cam size. Frankly, I neither see the point nor do I know what measurement you're looking for, or how you think I could get it. If you want to know the volume of material that needs to be moved before reaching the 35 degree slipping point, you would need to know more than just some dimension whatever that single dimension is you're looking for. GO

There is no significant relation between scanned angle and failure load (p-value=0.42) or percentage of rated strength (p-value=0.62), after adjusting for rated strength.

As I explained before, I suspect that the importance of rated strength in the analysis is that it is a surrogate for radius of curvature. The smaller the radius, the less the cam has to deform for the cam angle to attain the critical angle. If I understand his post, Jfield has also stated here that the radius should be an important predictor of failure load. I explained very precisely what measure I was looking for. I was thinking you could get it off the scans, but now that I think about it, there was probably no scale on the scan.

Edit: There is a significant negative correlation between post-test scanned angle and lobe hardness (r = -0.60, p-value = 0.01), suggesting that large post-test cam angles are the result of lobe softness. Post-test cam angle, therefore, probably isn't giving us much useful information.

Edit2: The (partial) correlation is even stronger (r = -0.70, p-value = 0.002), after controlling for rated strength.

Jay

(This post was edited by jt512 on Jun 22, 2009, 1:27 AM)

|

|

|

|

|

|

|

|

gunkiemike

Jun 22, 2009, 2:22 AM

Post #11 of 47

(18819 views)

Shortcut

Registered: Oct 1, 2002

Posts: 2266

|

cracklover wrote: According to Aric no other cams he's tested (and he's tested a bunch) fail by means of pulling from his jig. GO

As I recall, a blue Metolius TCU sheared out of the device.

|

|

|

|

|

cracklover

cracklover

Jun 22, 2009, 4:03 AM

Post #12 of 47

(18770 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

jt512 wrote: There is no significant relation between scanned angle and failure load (p-value=0.42) or percentage of rated strength (p-value=0.62), after adjusting for rated strength.

Not even among cams of the same size? Oh well.

In reply to: Edit: There is a significant negative correlation between post-test scanned angle and lobe hardness (r = -0.60, p-value = 0.01), suggesting that large post-test cam angles are the result of lobe softness. Post-test cam angle, therefore, probably isn't giving us much useful information.

Could you explain what you mean here? You're saying that the effective cam angle - the angle between the walls of the jig and the axle at the moment before testing, predicts the lobe hardness? That doesn't make sense. Surely I'm misunderstanding you.

In reply to: Edit2: The (partial) correlation is even stronger (r = -0.70, p-value = 0.002), after controlling for rated strength. Jay

And if you could clarify this as well, I'd be grateful.

GO

|

|

|

|

|

cracklover

cracklover

Jun 22, 2009, 4:05 AM

Post #13 of 47

(18769 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

gunkiemike wrote: cracklover wrote: According to Aric no other cams he's tested (and he's tested a bunch) fail by means of pulling from his jig. GO As I recall, a blue Metolius TCU sheared out of the device.

Aha! Aric, have you tested any other small cams in the jig?

GO

|

|

|

|

|

jt512

Jun 22, 2009, 4:49 AM

Post #14 of 47

(18738 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

cracklover wrote: jt512 wrote: There is no significant relation between scanned angle and failure load (p-value=0.42) or percentage of rated strength (p-value=0.62), after adjusting for rated strength. Not even among cams of the same size? Oh well. In reply to: Edit: There is a significant negative correlation between post-test scanned angle and lobe hardness (r = -0.60, p-value = 0.01), suggesting that large post-test cam angles are the result of lobe softness. Post-test cam angle, therefore, probably isn't giving us much useful information. Could you explain what you mean here? You're saying that the effective cam angle - the angle between the walls of the jig and the axle at the moment before testing, predicts the lobe hardness? That doesn't make sense. Surely I'm misunderstanding you.

I'm saying that the observed post-test cam angle is probably primarily the consequence of the softness of the cam lobe. Softer lobes deform more.

In reply to: Edit2: The (partial) correlation is even stronger (r = -0.70, p-value = 0.002), after controlling for rated strength.

Essentially, what this means is that, if you look at the correlation between scanned post-test angle and lobe hardness among cams of the same strength rating, the correlation is stronger than if you look at the correlation in the total sample. If that still doesn't make sense, let me know, and I'll give it another shot tomorrow, before I've drunk a half bottle or red wine (for the health benefits, of course).

Jay

|

|

|

|

|

cracklover

cracklover

Jun 22, 2009, 2:38 PM

Post #15 of 47

(18684 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

jt512 wrote: cracklover wrote: jt512 wrote: There is no significant relation between scanned angle and failure load (p-value=0.42) or percentage of rated strength (p-value=0.62), after adjusting for rated strength. Not even among cams of the same size? Oh well. In reply to: Edit: There is a significant negative correlation between post-test scanned angle and lobe hardness (r = -0.60, p-value = 0.01), suggesting that large post-test cam angles are the result of lobe softness. Post-test cam angle, therefore, probably isn't giving us much useful information. Could you explain what you mean here? You're saying that the effective cam angle - the angle between the walls of the jig and the axle at the moment before testing, predicts the lobe hardness? That doesn't make sense. Surely I'm misunderstanding you. I'm saying that the observed post-test cam angle is probably primarily the consequence of the softness of the cam lobe. Softer lobes deform more. In reply to: Edit2: The (partial) correlation is even stronger (r = -0.70, p-value = 0.002), after controlling for rated strength. Essentially, what this means is that, if you look at the correlation between scanned post-test angle and lobe hardness among cams of the same strength rating, the correlation is stronger than if you look at the correlation in the total sample. If that still doesn't make sense, let me know, and I'll give it another shot tomorrow, before I've drunk a half bottle or red wine (for the health benefits, of course). Jay

Oh, so when you refer to the "post-test" angle, you're referring to the angles I measured from the leading edge of the flat spot. That was from another thread, nothing to do with this one. This measurement (also on images taken "post test") is of the estimated effective angles at the time of pulling.

GO

|

|

|

|

|

hafilax

Jun 22, 2009, 5:44 PM

Post #16 of 47

(18594 views)

Shortcut

Registered: Dec 12, 2007

Posts: 3025

|

cracklover wrote: So the theory is that if the cam starts with a higher angle, less force is required, because less metal has to be deformed.

|

|

|

|

|

jt512

Jun 22, 2009, 6:08 PM

Post #17 of 47

(18568 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

cracklover wrote: jt512 wrote: cracklover wrote: jt512 wrote: There is no significant relation between scanned angle and failure load (p-value=0.42) or percentage of rated strength (p-value=0.62), after adjusting for rated strength. Not even among cams of the same size? Oh well. In reply to: Edit: There is a significant negative correlation between post-test scanned angle and lobe hardness (r = -0.60, p-value = 0.01), suggesting that large post-test cam angles are the result of lobe softness. Post-test cam angle, therefore, probably isn't giving us much useful information. Could you explain what you mean here? You're saying that the effective cam angle - the angle between the walls of the jig and the axle at the moment before testing, predicts the lobe hardness? That doesn't make sense. Surely I'm misunderstanding you. I'm saying that the observed post-test cam angle is probably primarily the consequence of the softness of the cam lobe. Softer lobes deform more. In reply to: Edit2: The (partial) correlation is even stronger (r = -0.70, p-value = 0.002), after controlling for rated strength. Essentially, what this means is that, if you look at the correlation between scanned post-test angle and lobe hardness among cams of the same strength rating, the correlation is stronger than if you look at the correlation in the total sample. If that still doesn't make sense, let me know, and I'll give it another shot tomorrow, before I've drunk a half bottle or red wine (for the health benefits, of course). Jay Oh, so when you refer to the "post-test" angle, you're referring to the angles I measured from the leading edge of the flat spot. That was from another thread, nothing to do with this one. This measurement (also on images taken "post test") is of the estimated effective angles at the time of pulling. GO

Gabe, I'm using the angle data from your first post in this thread. Are you saying that those numbers are estimates of the pre-test effective angles? If so, then (1) the explanation in your first post is unclear and misleading, and (2) I need to rethink the implications of my results.

Jay

|

|

|

|

|

cracklover

cracklover

Jun 22, 2009, 6:50 PM

Post #18 of 47

(18515 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

jt512 wrote: cracklover wrote: jt512 wrote: cracklover wrote: jt512 wrote: There is no significant relation between scanned angle and failure load (p-value=0.42) or percentage of rated strength (p-value=0.62), after adjusting for rated strength. Not even among cams of the same size? Oh well. In reply to: Edit: There is a significant negative correlation between post-test scanned angle and lobe hardness (r = -0.60, p-value = 0.01), suggesting that large post-test cam angles are the result of lobe softness. Post-test cam angle, therefore, probably isn't giving us much useful information. Could you explain what you mean here? You're saying that the effective cam angle - the angle between the walls of the jig and the axle at the moment before testing, predicts the lobe hardness? That doesn't make sense. Surely I'm misunderstanding you. I'm saying that the observed post-test cam angle is probably primarily the consequence of the softness of the cam lobe. Softer lobes deform more. In reply to: Edit2: The (partial) correlation is even stronger (r = -0.70, p-value = 0.002), after controlling for rated strength. Essentially, what this means is that, if you look at the correlation between scanned post-test angle and lobe hardness among cams of the same strength rating, the correlation is stronger than if you look at the correlation in the total sample. If that still doesn't make sense, let me know, and I'll give it another shot tomorrow, before I've drunk a half bottle or red wine (for the health benefits, of course). Jay Oh, so when you refer to the "post-test" angle, you're referring to the angles I measured from the leading edge of the flat spot. That was from another thread, nothing to do with this one. This measurement (also on images taken "post test") is of the estimated effective angles at the time of pulling. GO Gabe, I'm using the angle data from your first post in this thread. Are you saying that those numbers are estimates of the pre-test effective angles? If so, then (1) the explanation in your first post is unclear and misleading, and (2) I need to rethink the implications of my results. Jay

Sorry if my OP was not clear. I've added the following to the OP to hopefully clarify exactly what I'm measuring:

The angle I'm measuring is the angle between the center of the axle and the point of contact between the edge of the fixture at the moment before Aric began pulling.

Hopefully this pic will clarify. Depicted is the right side cam lobe, the axle, and the right side of the fixture. The angle I'm measuring is the angle between the axle and the fixture at the moment before the cam starts getting pulled.

GO

|

|

|

|

|

jt512

Jun 22, 2009, 8:27 PM

Post #19 of 47

(18456 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

cracklover wrote: Sorry if my OP was not clear. I've added the following to the OP to hopefully clarify exactly what I'm measuring: The angle I'm measuring is the angle between the center of the axle and the point of contact between the edge of the fixture at the moment before Aric began pulling. Hopefully this pic will clarify. Depicted is the right side cam lobe, the axle, and the right side of the fixture. The angle I'm measuring is the angle between the axle and the fixture at the moment before the cam starts getting pulled.  GO

Well, that makes the correlations I found difficult to interpret. Why would there be a strong (negative) correlation between pre-test cam angle and lobe hardness? Are you confident that you can accurately measure pre-test cam angle from scans of post-test cam lobes? Elsewhere, another poster (forgot his username) asserted that the cam angle measured from post-test images will be biased because the test will have caused displacement of the cam center. That would (I think) explain this correlation, and I can't think of any other reasonable explanation.

Jay

(This post was edited by jt512 on Jun 29, 2009, 6:40 AM)

|

|

|

|

|

adatesman

Jun 22, 2009, 9:21 PM

Post #20 of 47

(18416 views)

Shortcut

Registered: Jul 13, 2005

Posts: 3479

|

|

|

|

|

|

cracklover

cracklover

Jun 22, 2009, 9:27 PM

Post #21 of 47

(18408 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

jt512 wrote: cracklover wrote: Sorry if my OP was not clear. I've added the following to the OP to hopefully clarify exactly what I'm measuring: The angle I'm measuring is the angle between the center of the axle and the point of contact between the edge of the fixture at the moment before Aric began pulling. Hopefully this pic will clarify. Depicted is the right side cam lobe, the axle, and the right side of the fixture. The angle I'm measuring is the angle between the axle and the fixture at the moment before the cam starts getting pulled. [IMG]http://i42.tinypic.com/2hfqwc9.jpg[/IMG] GO Well, that makes the correlations I found difficult to interpret. Why would there be a strong (negative) correlation correlation between pre-test cam angle and lobe hardness? Are you confident that you can accurately measure pre-test cam angle from scans of post-test cam lobes? Elsewhere, another poster (forgot his username) asserted that the cam angle measured from post-test images will be biased because the test will have caused displacement of the cam center. That would (I think) explain this correlation, and I can't think of any other reasonable explanation. Jay

Not sure, but I think you're referring to a post in which someone mentioned that the cam angle would be changed by the bending of the axle, which is irrelevant to the angle I'm measuring which is the *starting* angle.

So let me get this straight, you're saying the higher the starting cam angle, the softer the lobes?

Not only is it hard to see what would cause that, but I'm also not sure about your data. For example, two of the samples with the highest cam angles, (sample four and five, the two purple cams) had relatively hard lobes. And most of those with particularly hard lobes (9, 20, and 21) had average cam angles around 18 degrees.

GO

(edited for clarity)

(This post was edited by cracklover on Jun 22, 2009, 10:04 PM)

|

|

|

|

|

cracklover

cracklover

Jun 22, 2009, 9:31 PM

Post #22 of 47

(18398 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

adatesman wrote: cracklover wrote: According to Aric no other cams he's tested (and he's tested a bunch) fail by means of pulling from his jig. Not quite... A pair of old U-stem camalots pulled from the fixture, but that was due to the divot in the lobes allowing the axles to flex further than they should have been able. And as Gunkie mentioned, the Blue TCU we tested while doing the Aliens also slipped from the fixture with a flattened lobe, but that occurred well above its rating. Most everything else I've done stayed put and broke in the fixture.

Thanks for the clarification. I think, in terms of controls, the main issue is around testing other small cams, since it seems that in Aliens the best predictor of whether the cam will slip out of the fixture at low loads is how small the cam is.

You can't prove that other cam designs don't suffer from the same "defect" (whether the defect is in the test setup or the cam design) by testing large cams from other manufacturers.

GO

|

|

|

|

|

adatesman

Jun 22, 2009, 9:40 PM

Post #23 of 47

(18391 views)

Shortcut

Registered: Jul 13, 2005

Posts: 3479

|

|

|

|

|

|

glytch

Jun 22, 2009, 9:40 PM

Post #24 of 47

(18388 views)

Shortcut

Registered: Aug 29, 2006

Posts: 194

|

So, I think I have this straight: what you're trying to accomplish here is an examination of the relationship - if any - between initial effective cam angle and force at which the piece pulled.

My question is regarding step 2 of the process you outline. Why is the theoretical center point of the cam relevant if you're measuring instantaneous cam angle? As I see it, attempting to do this with the images of cam-in-fixture, you need to find the centerpoint of the axle (this will be tough to do well with the off-center pictures) and (to do this well) use a bit of projective geometry to find the angle formed between the lobe contact point and the actual center of the axle... I don't see where the theoretical center of the spiral comes into play.

My suspicion is that the angular difference will be sufficiently small between cams that attempting to measure it will yield results well within the margins of human error. Interestingly, most lobe centers seem to be off in such a way that the resultant change in cam angle will be relatively small in moderately contracted cam. I'd draw an image, but I'm lazy :)

|

|

|

|

|

cracklover

cracklover

Jun 22, 2009, 10:02 PM

Post #25 of 47

(18365 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

glytch wrote: So, I think I have this straight: what you're trying to accomplish here is an examination of the relationship - if any - between initial effective cam angle and force at which the piece pulled.

Correct.

In reply to: My question is regarding step 2 of the process you outline. Why is the theoretical center point of the cam relevant if you're measuring instantaneous cam angle?

Because if you draw a straight line from the theoretical middle of the spiral to the contact point, and a line from the actual middle to the contact point, you can measure the difference in the angle between those two lines to determine what the true angle in the fixture was. For example, on this cam:

The two angles are traced in in red. The angle from the dorrington center to the fixture would have been 16 degrees (by definition, since it's a 16 degree spiral). The angle from the middle of the axle was 3.5 degrees higher. So the true angle in the fixture was 19.5 (16 + 3.5) degrees.

Make sense?

In reply to: As I see it, attempting to do this with the images of cam-in-fixture, you need to find the centerpoint of the axle (this will be tough to do well with the off-center pictures) and (to do this well) use a bit of projective geometry to find the angle formed between the lobe contact point and the actual center of the axle... I don't see where the theoretical center of the spiral comes into play.

I think you misunderstand. Hopefully after my explanation, things are a little more clear. The utility of the photos Aric took in the jig is simply to visually confirm where the contact point is on the edge of the cam lobes.

GO

|

|

|

|

|

healyje

Jun 22, 2009, 10:06 PM

Post #26 of 47

(4393 views)

Shortcut

Registered: Aug 22, 2004

Posts: 4204

|

On their way to Aric:

2 - #4 Friends

1 - Link Cam (the one Bill Coe and I tried to break with our hands and pliers)

1 - #7 ABC

1 - Red/Yellow Alien Hybrid

1 - #2 Metolius Power Cam (Dated 07/03 and fallen on)

1 - #0 Metolius Ultralight Power Cam (Dated 04/06)

1 - #1 Metolius Master Cam (Fallen on hard, savagely abused by folks trying to get it out for a year, finally brutally funked out while wet)

|

|

|

|

|

healyje

Jun 22, 2009, 10:11 PM

Post #27 of 47

(4386 views)

Shortcut

Registered: Aug 22, 2004

Posts: 4204

|

The #1 Master Cam for all the whining about the poor 'used' Alien that failed - wanna bet the 'used' Master Cam still tests above it's rating...?

|

|

|

|

|

glytch

Jun 22, 2009, 10:27 PM

Post #28 of 47

(4378 views)

Shortcut

Registered: Aug 29, 2006

Posts: 194

|

Gabe,

That clears things up quite a bit, thanks! You're using the angular difference instead of measuring the angle outright. I'm still skeptical as to the accuracy of this process based on the human error inherent in eyeballing a contact point, but the process makes a lot more sense to me now.

The real way to get this data - and this would be totally awesome, though also hard and expensive to build - would be to measure force normal to the plates. In conjunction with the force the puller's exerting, you'd get the real effective cam angle...

Aside from the difficulties in measuring this angle, I think the effect of initial cam angle on pullout force is both fundamental and interesting, but I also think it's going to be heavily obscured by the deformation of the cam. That said, if JT's strange statistical anomaly holds up (the negative correlation between initial angle and hardness), it could shed some light on a peculiar quirk of the manufacturing process. Maybe metal stock from a certain source is processed on one line, etc...

All of that aside, you won't see me racking aliens any time soon!

|

|

|

|

|

jt512

Jun 22, 2009, 11:52 PM

Post #29 of 47

(4350 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

cracklover wrote: jt512 wrote: cracklover wrote: Sorry if my OP was not clear. I've added the following to the OP to hopefully clarify exactly what I'm measuring: The angle I'm measuring is the angle between the center of the axle and the point of contact between the edge of the fixture at the moment before Aric began pulling. Hopefully this pic will clarify. Depicted is the right side cam lobe, the axle, and the right side of the fixture. The angle I'm measuring is the angle between the axle and the fixture at the moment before the cam starts getting pulled. [IMG]http://i42.tinypic.com/2hfqwc9.jpg[/IMG] GO Well, that makes the correlations I found difficult to interpret. Why would there be a strong (negative) correlation correlation between pre-test cam angle and lobe hardness? Are you confident that you can accurately measure pre-test cam angle from scans of post-test cam lobes? Elsewhere, another poster (forgot his username) asserted that the cam angle measured from post-test images will be biased because the test will have caused displacement of the cam center. That would (I think) explain this correlation, and I can't think of any other reasonable explanation. Jay Not sure, but I think you're referring to a post in which someone mentioned that the cam angle would be changed by the bending of the axle, which is irrelevant to the angle I'm measuring which is the *starting* angle.

No, I was referring to the following comment this post.

verticon wrote: The axle holes of the softer lobes were deformed during the test, as their edges were compressed with the same forces as for the fixture side (less deformation though, because of the even contact surface with the axle). So far, you've been looking for a correlation between the hardness of the lobes and the failure cam angle, ignoring the translation of the center point toward the fixture, but the angle is further increased by the ovalization of the axle hole.

cracklover wrote: So let me get this straight, you're saying the higher the starting cam angle, the softer the lobes?

Specifically, the higher the starting angles as measured from post-test images, the softer the lobes. The correlation is -0.80 (p=0.002). In contrast, there is no correlation between the starting angle, as measured from pre-test images, and hardness (r=-0.06, p=0.82). Hence, I am skeptical about the accuracy of the angles measured from the post-test scans.

Furthermore, the angles from the pre- and post-test images are significantly correlated (r=0.55, p=0.03). This suggests that the lack of correlation between angle from pre-scan image and hardness is not likely to be due to random error in the measurement of the pre-test angle.

Jay

Note: Correlations are partial correlation coefficients, controlled for strength rating.

|

|

|

|

|

hafilax

Jun 23, 2009, 12:02 AM

Post #30 of 47

(4347 views)

Shortcut

Registered: Dec 12, 2007

Posts: 3025

|

Is it possible that the misalignment of the axle holes in the soft stock could have anything to do with over-tightening a clamp or something in the machining process?

|

|

|

|

|

cracklover

cracklover

Jun 23, 2009, 12:10 AM

Post #31 of 47

(4347 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

Jay, have you looked at the photos? Yes, some of the cams have an oval where they should have a circle, where the axle hole is. But they're so close to being a circle that in no case would moving the real center between the obvious original center of the circle that I plotted (you can see how the cam got deformed), and the center of the oval, change the results by even a half a degree.

And why would random error in my first set of data not obscure any real correlation in a more accurate set of data, while still having a good correlation to that more accurate set of data? That doesn't make any sense.

GO

|

|

|

|

|

jt512

Jun 23, 2009, 12:52 AM

Post #33 of 47

(4334 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

cracklover wrote: And why would random error in my first set of data not obscure any real correlation in a more accurate set of data, while still having a good correlation to that more accurate set of data?

Because it would also have obscured the correlation between the angles measured from the pre- and the post-test images.

Jay

(This post was edited by jt512 on Jun 23, 2009, 12:52 AM)

|

|

|

|

|

glytch

Jun 23, 2009, 1:34 AM

Post #34 of 47

(4314 views)

Shortcut

Registered: Aug 29, 2006

Posts: 194

|

Jay,

Could you please clarify which data is correlated with hardness? Or, specifically, what does

In reply to: as measured from post-test images

mean?

I'm confused as to which data sets you're using, and I'm only marginally clear on the data processing that Gabe's done... you seem to have a better handle on what data's out there and what it means - I'd appreciate it if you could clarify.

Thanks!

|

|

|

|

|

jt512

Jun 23, 2009, 2:44 AM

Post #35 of 47

(4293 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

glytch wrote: Jay, Could you please clarify which data is correlated with hardness? Or, specifically, what does In reply to: as measured from post-test images mean? I'm confused as to which data sets you're using, and I'm only marginally clear on the data processing that Gabe's done... you seem to have a better handle on what data's out there and what it means - I'd appreciate it if you could clarify. Thanks!

Cracklover has used scanned images of the cam lobes after the cam was pull tested to estimate what the actual cam angle was when the cam was placed in the test apparatus, but before tension was applied to the cam. I have called those angles the angles from the post-test images. Those data are in the first post in this thread. And it is those data that are correlated (negatively) with hardness.

I have been referring to Cracklover's other set of angle data, which are here, as angles from the pre-test images, because I was thinking that was what they were. But I may have been mistaken. It just dawned on me that Gabe mentioned that he had another set of angles where he measured the angle at the leading of the flat spot. So those would be post-test images also.

Gabe, can you clarify how the angles in the link in the preceding paragraph were obtained?

Jay

|

|

|

|

|

cracklover

cracklover

Jun 23, 2009, 3:16 AM

Post #36 of 47

(4281 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

jt512 wrote: Gabe, can you clarify how the angles in the link in the preceding paragraph were obtained? Jay

Yeah, I took the range of angles from Aric's report, (in which some of the cams were slightly tilted, enough to create a few degrees of skew), estimated the point of contact based on the photo (in which, typically, only one lobe could be seen well) and put those two together.

GO

|

|

|

|

|

jt512

Jun 23, 2009, 3:19 AM

Post #37 of 47

(4279 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

cracklover wrote: jt512 wrote: Gabe, can you clarify how the angles in the link in the preceding paragraph were obtained? Jay Yeah, I took the range of angles from Aric's report, (in which some of the cams were slightly tilted, enough to create a few degrees of skew), estimated the point of contact based on the photo (in which, typically, only one lobe could be seen well) and put those two together. GO

Whew! Thanks.

Jay

|

|

|

|

|

rightarmbad

Jun 23, 2009, 11:29 AM

Post #38 of 47

(4250 views)

Shortcut

Registered: Mar 22, 2005

Posts: 218

|

If I were to design a cam tomorrow, I would think a little about making the angle under load the important factor.

If the angle changes as the cam loads up due to flex, then I would alter the initial design to reflect the changes that happen under load.

Similar to making pistons in engines oval to allow for uneven expansion, if you get my drift.

So my question is: What are the operating angles of all the cams on the market, under load?

The initial angles should all be different to reflect the differing amounts of flex in the design and the materials chosen. ( that is, if the angle really is the most important part of the holding equation)

Food for thought....

|

|

|

|

|

mojomonkey

Jun 23, 2009, 1:33 PM

Post #39 of 47

(4235 views)

Shortcut

Registered: Aug 13, 2006

Posts: 869

|

adatesman wrote: At the moment the puller is out of commission while I resurface the fixture yet again, but it should be back together by the end of the week. The new texture will be a milled diamond knurl ~0.020" deep @ 20 tpi (to put 0.005" flats at the top of the knurls to help with wear), which will be approximately the max allowable roughness in the UIAA spec. I'm going to do the other side of the plates to something like ~0.010" since the actually cutting of the texture is quick and easy once the PITA of modifying the milling machine to do them is taken care of.

If you are going to compare more small gear to see if it pulls from the fixture, the texture should be left at what the aliens were tested against. Why throw in a new variable at this point?

|

|

|

|

|

adatesman

Jun 23, 2009, 3:06 PM

Post #40 of 47

(4211 views)

Shortcut

Registered: Jul 13, 2005

Posts: 3479

|

|

|

|

|

|

jt512

Jun 23, 2009, 4:08 PM

Post #41 of 47

(4179 views)

Shortcut

Registered: Apr 12, 2001

Posts: 21904

|

adatesman wrote: jt512 wrote: I was thinking you could get it off the scans, but now that I think about it, there was probably no scale on the scan. Starting to get caught up with this after taking a couple days (mostly) away from it... I'm rather annoyed with myself over this, as I had a steel ruler actually on the scanner bed while doing these but it was out of the cropped frame. Dammit! FWIW I did include the axles in the original scans and for all but the Blue and Black they're nominal 0.250" diameter. Scaling off that would be a bit of a pain, but not too bad.

It think that due to deformation of the lobes from testing that it will be difficult to get accurate measurements of the radius from those scans. For cams that have already been tested, I suggest using standardized radius lengths rather than actual measurements. That is, just take an untested cam of the same size as the tested one and measure the radius at the mid-expansion point. In future tests, the actual radius could be determined from the jig settings.

Jay

|

|

|

|

|

villageidiot

Jun 29, 2009, 6:32 AM

Post #42 of 47

(4061 views)

Shortcut

Registered: May 12, 2005

Posts: 104

|

cracklover wrote: villageidiot wrote: What's the merit in reporting the average of the cam angles? Well, some of the cams appear to be pulling from the fixture when they flatten enough to create a 35 degree angle at the leading edge of the flat point. So the theory is that if the cam starts with a higher angle, less force is required, because less metal has to be deformed.

The first figure shows a log spiral with the center denoted by a black cross. If the axle of such a cam is then located at a distance y and x from the center (blue cross with circle), one can then relate the actual cam angle (beta) to the designed cam angle (theta) by the following equation:

tan(beta) = ( r*sin(theta) + y) / (r*cos(theta)+x)

which can be rearranged,

tan(beta) = ( sin(theta) + y/r) / (cos(theta)+x/r)

Then using either calculus (or Matlab if you are lazy like me) one can generate a plot of the constant effective cam angle lines as a function of y/r and x/r, as shown in the second plot. Note the plot is only for a 16DEG angle cam.

It appears you have attempted to measure the distance between centers (log spiral and axle) in previous posts (d= sqrt(x^2+y^2) and this distance may be represented by the black circles superimposed on the lines in figure 2. One can see that depending on whether the quantities y/r and x/r are positive or negative the range of the effective cam angle varies.

If one attempts to measure the cam angle of such a cam as it is expanded, one would expect to find a range of values. Taking the arithmetic mean of that data set would reflect the cam angle at only one point, which may not correspond to any of the points where the measurement was taken. By averaging the different values you are eliminating information and not gaining anything in return. I would suggest therefore reporting the range of values measured and not the mean.

I suspect that the only case when taking the mean would be justified would be when the error in your measurement of the effective cam angle is on the same order as the range of possible effective cam angles. However, in such a case the cam might as well be constant angle because you cannot measure otherwise.

|

|

Attachments:

|

cam.jpg

(8.65 KB)

cam.jpg

(8.65 KB)

|

|

|

cam2.jpg

(43.1 KB)

cam2.jpg

(43.1 KB)

|

|

|

|

|

villageidiot

Jun 29, 2009, 6:44 AM

Post #43 of 47

(4054 views)

Shortcut

Registered: May 12, 2005

Posts: 104

|

cracklover wrote: In reply to: I am not much of a math person, but I believe you need 5 degrees of freedom to predict the actual cam angle of a log spiral with the axle off center (2 DOF to describe the cam, 2 DOF to describe where the axle is in relationship to the center of the spiral, and 1 DOF to describe how open the cam is). Sorry, could you try that again in plain English? Or else just tell me what you see wrong with the methodology I actually used. Thanks, GO

If you have a cam and the axle is not located at the center of the log spiral measuring it at one location (or averaging a bunch of positions, see previous post) will not provide any information other than the effective cam angle at that position. Five parameters need to be specified to predict the effective can angle of such a cam.

|

|

|

|

|

villageidiot

Jun 29, 2009, 6:48 AM

Post #44 of 47

(4049 views)

Shortcut

Registered: May 12, 2005

Posts: 104

|

Can you measure a cam angle to a tenth of a degree? An estimate of error in these measurements would probably be helpful. What I mean is the value 14.5 (+/-0.2) DEG or 14.5 (+/-2) DEG?

|

|

|

|

|

cracklover

cracklover

Jun 29, 2009, 2:40 PM

Post #45 of 47

(4015 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

villageidiot wrote: It appears you have attempted to measure the distance between centers (log spiral and axle) in previous posts (d= sqrt(x^2+y^2) and this distance may be represented by the black circles superimposed on the lines in figure 2. One can see that depending on whether the quantities y/r and x/r are positive or negative the range of the effective cam angle varies.

Not exactly. I don't care about the *distance* between centers, except inasmuch as it creates a change in effective cam angle in the placement used by Aric in the test that broke the cam.

In reply to: If one attempts to measure the cam angle of such a cam as it is expanded, one would expect to find a range of values. Taking the arithmetic mean of that data set would reflect the cam angle at only one point, which may not correspond to any of the points where the measurement was taken.

That's true, but that's not what I did.

What I did was find the true cam angle for several lobes of each cam, and average the angles of those lobes together.

In reply to: By averaging the different values you are eliminating information and not gaining anything in return.

Again, yes, that would have been a stupid thing to do. Did you look at the photos I uploaded? For each cam lobe, I'm measuring a *specific* cam angle.

Did you read any of the text of my post? In reply to: The angle I'm measuring is the angle between the center of the axle and the point of contact between the edge of the fixture at the moment before Aric began pulling. <snip> The angle I'm measuring is the angle between the axle and the fixture at the moment before the cam starts getting pulled. <snip> Third, I found the contact point for each lobe, using a combination of the photos Aric took of the cam placed in the jig, and the flat spot on the cam lobe. Wherever possible, I used the actual flat spot. Fourth, I determined the effective cam angle in the jig for each lobe, and averaged them together. For each cam Aric put photos online, I used between two and four lobes. If the lobes were too bent, or if the results were identical across lobes, I did not use all four. Lastly, I averaged these angles together to find the effective cam angle for each piece Aric tested.

At no time did I suggest that I was using the range of angles and averaging them.

In reply to: I would suggest therefore reporting the range of values measured and not the mean.

That would be interesting in the abstract, but A - Aric already did that in his original test writeup, and B - Those ranges do nothing to tell us the *actual* effective cam angle each cam felt when it was pulled. That's the whole point of the research I did.

In reply to: I suspect that the only case when taking the mean would be justified would be when the error in your measurement of the effective cam angle is on the same order as the range of possible effective cam angles. However, in such a case the cam might as well be constant angle because you cannot measure otherwise.

No. You can measure otherwise. And I did.

GO

|

|

|

|

|

cracklover

cracklover

Jun 29, 2009, 2:43 PM

Post #46 of 47

(4012 views)

Shortcut

Registered: Nov 14, 2002

Posts: 10162

|

villageidiot wrote: cracklover wrote: In reply to: I am not much of a math person, but I believe you need 5 degrees of freedom to predict the actual cam angle of a log spiral with the axle off center (2 DOF to describe the cam, 2 DOF to describe where the axle is in relationship to the center of the spiral, and 1 DOF to describe how open the cam is). Sorry, could you try that again in plain English? Or else just tell me what you see wrong with the methodology I actually used. Thanks, GO If you have a cam and the axle is not located at the center of the log spiral measuring it at one location (or averaging a bunch of positions, see previous post) will not provide any information other than the effective cam angle at that position. Five parameters need to be specified to predict the effective can angle of such a cam.

1 - I didn't average a "bunch of positions".

2 - I measured the effective cam angle at one position. But it was not some random position, it was the position in which the cam was actually placed during the test.

GO

|

|

|

|

|

|